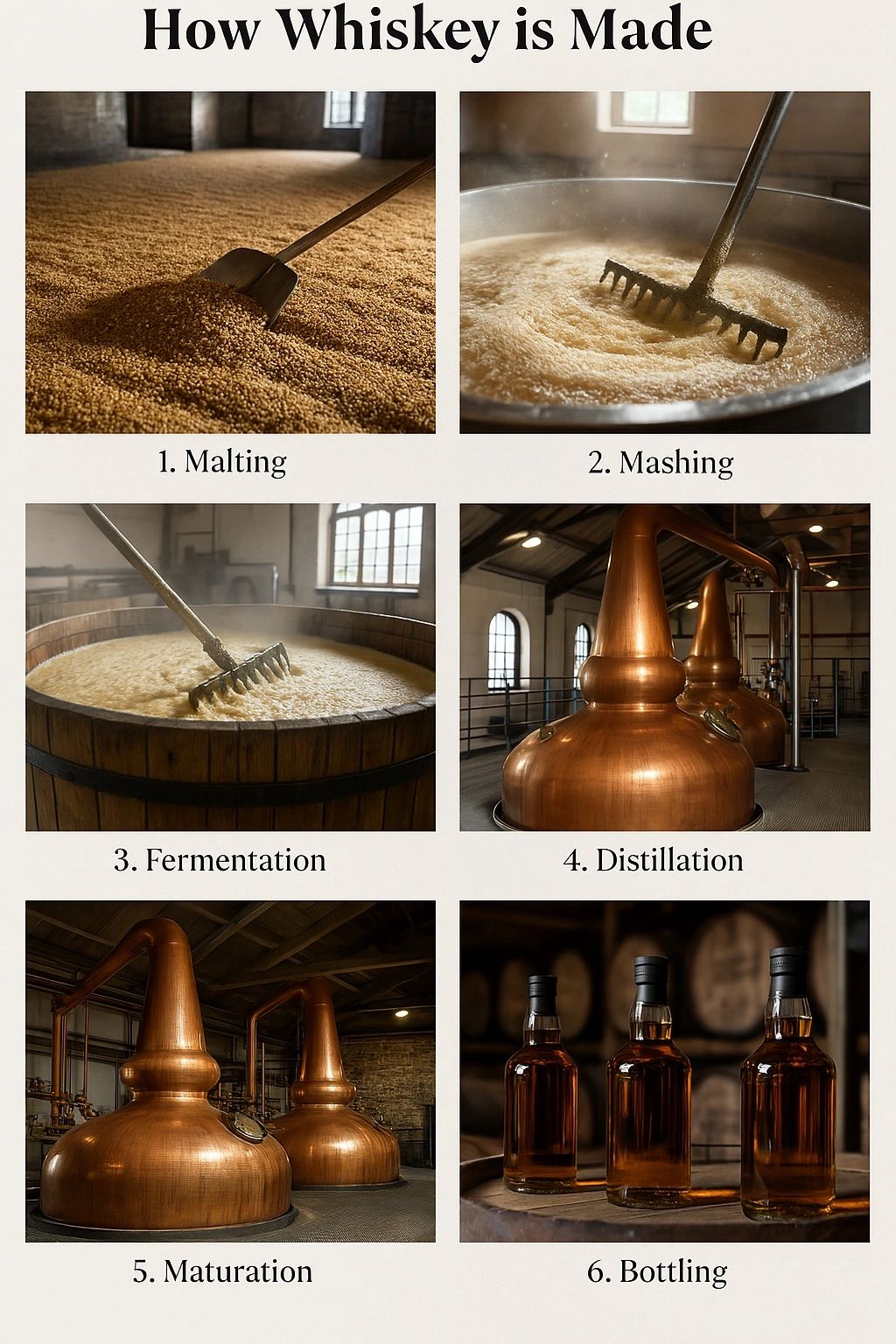

From Grain to Glass: How Whiskey is Made

Whiskey may be known for its smooth character and rich flavor, but behind every bottle lies a fascinating process of transformation—one that blends art, science, tradition, and time. Whether it’s a smoky Scotch or a sweet Kentucky bourbon, the whiskey-making process follows a shared foundation.

Let’s take a deep dive into how whiskey is made—step by step, from grain to glass.

⸻

1. Malting: Unlocking the Starch

Whiskey starts with grain—usually barley, corn, rye, or wheat. For malt whiskey, barley is the primary grain. The first step is malting, where the grain is soaked in water and allowed to germinate.

This process activates enzymes that convert starches in the grain into fermentable sugars.

• Malted barley is then dried in a kiln.

• In Scotch, peat may be burned during drying, adding the signature smoky flavor.

⸻

2. Mashing: Making the Sugar Soup

Next comes mashing. The dried malt (or a mix of grains, depending on the whiskey type) is ground into coarse flour called grist and mixed with hot water in a mash tun.

This extracts the sugars and forms a thick, sweet liquid called wort.

• The wort is drawn off while the spent grains are often recycled for livestock feed.

• Multiple water infusions ensure maximum sugar extraction.

⸻

3. Fermentation: Birth of the Alcohol

The wort is cooled and transferred into large vessels called washbacks or fermentation tanks, where yeast is added.

Yeast feeds on the sugars and converts them into alcohol, creating a beer-like liquid known as wash, usually around 6–10% ABV.

This stage also produces important flavor compounds that will carry through to the final spirit.

⸻

4. Distillation: Concentrating the Spirit

The wash is then transferred to copper pot stills or column stills for distillation. The goal? To purify the alcohol and concentrate the flavor.

• Pot stills are traditional and used for Scotch single malts and Irish whiskey.

• Column stills are continuous and more efficient—often used for bourbon and grain whiskies.

The process:

• The first distillation (wash still) separates alcohol from solids.

• The second distillation (spirit still) refines it further.

• The “heart cut” is collected—the part of the distillate that becomes whiskey.

⸻

5. Maturation: The Magic of the Barrel

Freshly distilled whiskey is clear—it only becomes golden and flavorful through aging in oak barrels.

Barrels are often:

• Charred (bourbon) to develop vanilla and caramel notes.

• Used sherry or wine casks (Scotch/Irish) to impart dried fruit or nutty flavors.

By law:

• Bourbon must be aged in new charred oak barrels.

• Scotch and Irish whiskey must be aged at least 3 years.

Over time, whiskey breathes with the environment, interacting with the wood. This is where it gains its color, complexity, and maturity.

⸻

6. Bottling: From Barrel to You

Once matured, the whiskey is:

• Diluted to bottle strength (usually around 40–46% ABV),

• Filtered (unless it’s labeled non-chill filtered),

• And bottled for sale.

Some whiskeys are single barrel (from one cask), others are blended for consistency.

⸻

Conclusion: Every Drop Tells a Story

From humble grain to golden dram, the whiskey-making process is a beautiful blend of nature, craft, and time. Every decision—from the grain to the barrel—shapes what you taste in the glass.

Next time you sip your favorite whiskey, you’re not just enjoying a drink—you’re experiencing a story that began years ago, in a quiet distillery, one barrel at a time.